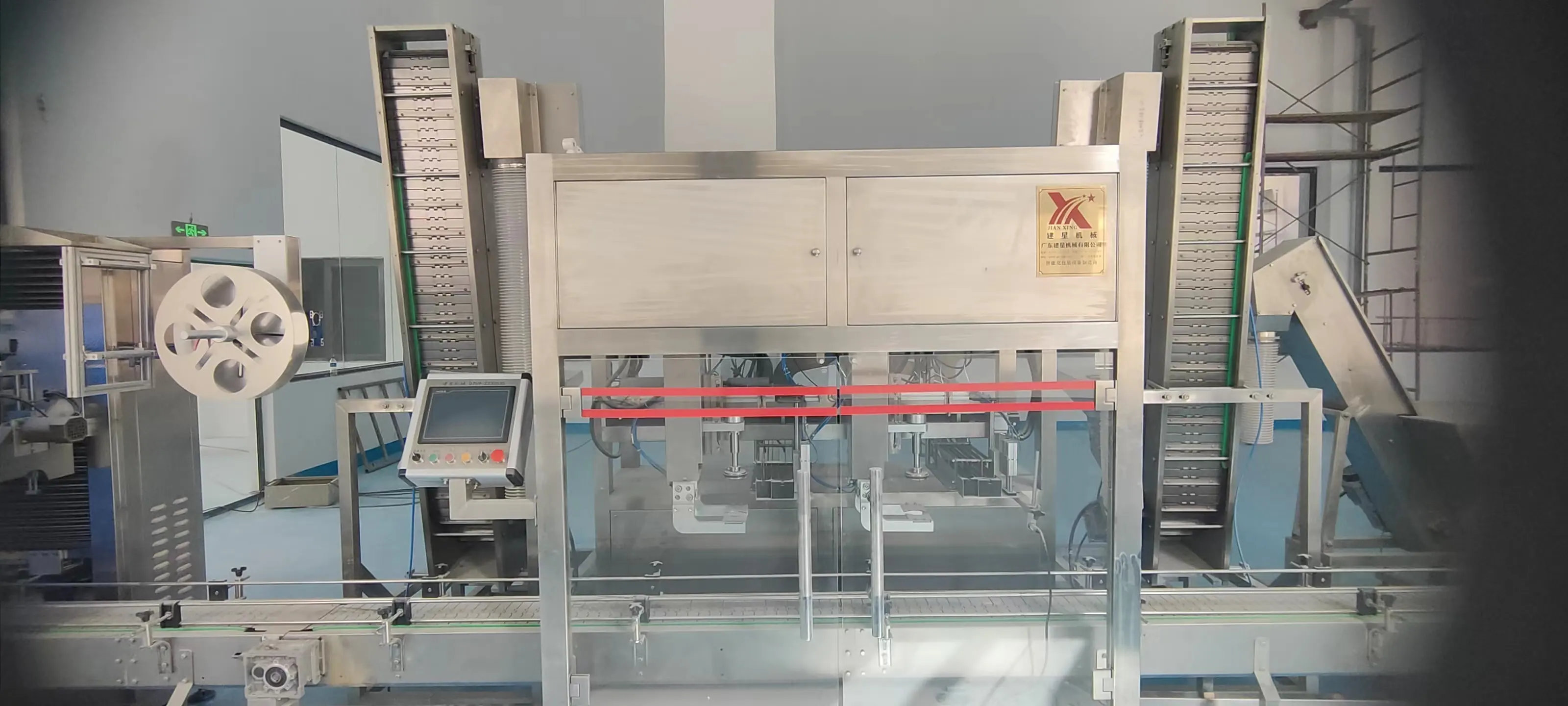

Tin Cap Sealing Machine - - Jianxing

Product Overview

- The tin cap sealing machine is designed for safe transportation and rigorous quality management to meet intended quality standards.

- It is an integrated machine with automatic tracking type cap sorting and cap screwing/pressing mechanisms.

Product Features

- Can be customized to fit different sizes of caps and equipped with detection sensors for quantity control and automatic shut off to avoid powder generation.

- Main components include transmission mechanism, cap screwing/pressing mechanism, bottle inlet and outlet mechanism, servo tracking type cap sorting mechanism, and electric control system.

Product Value

- The machine is compatible with 2 sizes of caps and can be customized for capping speed and other specifications according to customer's production capacity.

Product Advantages

- The machine is equipped with high-quality main components from reputable brands like Siemens, Omron, and Delta, ensuring efficient and reliable operation.

- The company has a strong research and development team, and products are not only sold well domestically but also exported to various countries.

Application Scenarios

- Suitable for sealing and capping operations in industries such as food and beverage, pharmaceuticals, and manufacturing, with the capability of customizing cap diameter and bottle height.