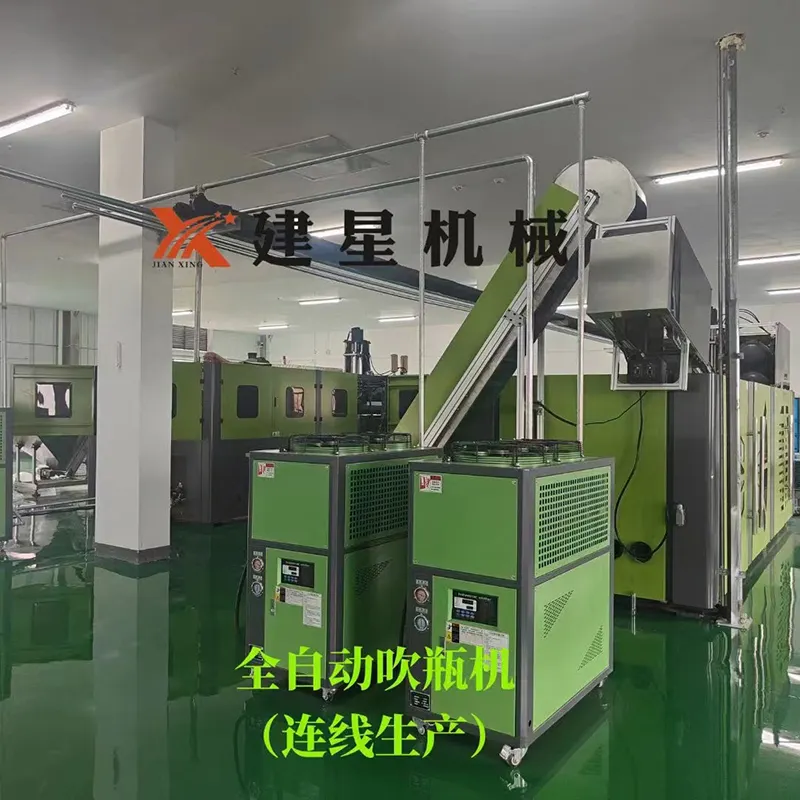

Topbottle Molding Machine

Product Overview

The Topbottle Molding Machine is a PET bottle blowing machine with a capacity of 1300-6000BPH, customizable according to customer's production capacity and bottle type. It includes the main components of bottle blowing host, heating furnace, automatic bottle preform feeding machine, and bottle preform sorting machine.

Product Features

- Robotic arms complete bottle preform picking, loading, picking, and arrangement automatically to avoid intermediate pollution

- Mold is made of magnesium aluminum alloy with fast replacement

- Key components selected from well-known foreign manufacturers

- Equipment operation and adjustment can be done through the SIMATIC HMI operation panel

- Transmission mechanism works continuously without displacement and with stability

Product Value

The product has low energy consumption and is equipped with high-quality components from well-known manufacturers, ensuring high performance and efficiency.

Product Advantages

The Topbottle Molding Machine offers fast mold replacement, automated processes to avoid pollution, stability, and low energy consumption. It also has a unique heating mechanism and high-quality components.

Application Scenarios

The machine is widely used for PET bottles and can be used in various production scenarios due to its customizable capacity and high performance.