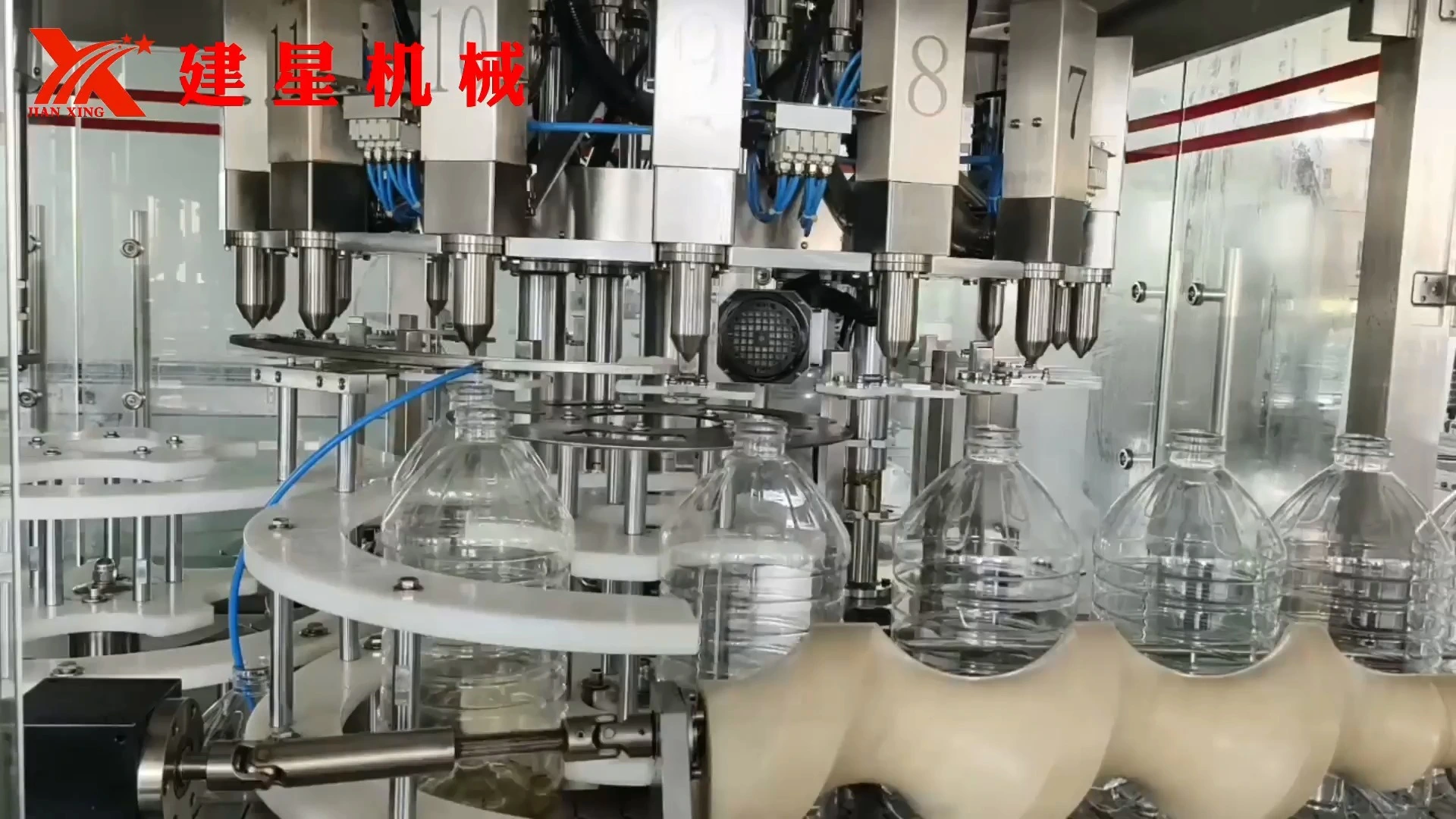

HBM Load Cell Based High Speed Rotary Weighing Type Filling Machine

Product Model

|

Model |

JX-W16-(4/5/6) |

JX-W20-(4/5/6) |

JX-W24-(6/8) |

JX-W28-(6/8/10) |

JX-W32-(6/8/10) |

|

Filling Nozzles |

16 |

20 |

24 |

28 |

32 |

|

Capacity (Based on 5L) |

3000 |

4000 |

4500-5000 |

5000-5500 |

6000 |

|

Filling Range |

1L~10L |

1L~10L |

1L~10L |

1L~10L |

1L~10L |

|

Filling Accuracy |

±2g |

±2g |

±2g |

±2g |

±2g |

|

Measurement Method |

Weighing Type |

||||

|

Capping Method |

Press Cap/Screw Cap |

||||

|

Applicable Containers |

PET bottle, HDPE bottle, PE bottle, tin can, glass bottle |

||||

|

Applicable Liquids |

edible oil, lubricant oil, engine oil, alcoholic drinks, beverage, daily chemical and agrochemical liquids,etc. |

||||

|

Power |

5.5KW |

5.5KW |

6.5KW |

6.5KW |

6.5KW |

|

Air Pressure |

0.6Mpa~0.8Mpa |

0.6Mpa~0.8Mpa |

0.6Mpa~0.8Mpa |

0.6Mpa~0.8Mpa |

0.6Mpa~0.8Mpa |

|

Size |

The actual size is customized according to the customer's sample containers and subject to the actual product. |

||||

Technical Parameter

|

Measurement Mode |

HBM load cell |

|

Integrated Machine |

Rotary weighing type filling and capping integrated machine |

|

Conversion and Adjustment |

Data storage and recovery system |

|

Control System |

Siemens |

|

Fault Alarm |

Three-color alarm light+buzzing alarm sound |

|

Speed Level |

Fast --slow |

|

Appearance |

Stainless steel + tempering glass door (Dust free filling) |

|

Oil Storage Tank and Liquid Material Pipeline |

Stainless steel |

|

Bottle cap feeding elevator |

|

Main Features

Main Configuration

|

Load Cell |

HBM (Germany) |

|

|

PLC |

Siemens (Germany) |

|

|

Pneumatic Components |

FESTO (Germany) |

|

|

Low Voltage Electrical Components |

Schneider(France) |

|

|

Frequency Converter |

Delta (Taiwan) |

|

|

Operation Screen |

Siemens (Germany) |

|

|

Photoelectric Detection Element |

Omron(Japan) |

|

|

Main Drive |

SEW (Germany) |

|

|

Main Power Switch |

Schneider(France) |

|

|

Contactor,Overload Relay,Circuit Breaker |

Schneider(France) |

|